On April 7th 2014 I officially registered Emergo Designs as a company! It has been 7 years of making, learning from mistakes and growing closer to my goals and dreams. I thought it to be nice to give a brief overview of the company and my journey.

At the start of 2014, I was making knives and came up with the idea for an handmade oyster knife. Our family has been fishing oysters for over 100 years and I grew up on the fishing vessel ”Ye 123 Hugo Senior”. I’ve spend my summer holiday fishing and growing oysters with my dad and uncles. For me it was pretty straight forward to combine my heritage(oysters) with my hobbies(knife making) and my education(engineering and design).

Quickly after the start of the company I moved to our oyster packing facility. This is a magical place near the water with beautiful scenery. Here I started making the first real oyster knives for customers and I received the first orders in this place. Back then 100% was made by hand and it took me around 20+ hours for a knife. Some of the views and the early process can be seen in this video:

Moving shop

Later I moved my workshop when my wife and I moved in together. It had a really nice feel to it and the new location was used by different makers and artists. Lots of dust, tools and inspiration. It was also the first spot that was really ”for me”. This meant that I could drop my tools and go home without having to rearrange everything. Machines could be put in the best position for quick and repeatable production.

A good example of this is that I used to have one work bench with place for 1 machine. So when I wanted to grind, I would put the grinder on. When I wanted to drill, I would place the drill press on the table. It felt like I was more busy with setting up machines than that I was knife making. In this new workshop I learned a lot about machine placement and making a oyster knife making process. A good example is this video:

Another workshop and a new course

In 2020 I once again moved shop. The second workshop was in an old warehouse and we were allowed to use it until they would start and build something new there. This was always a double edged sword to me. The rent was cheap and it was super close to home(2 minutes drive), but I never put a lot of money into the shop because we could be kicked out on short notice. Because of this, the winters were really cold and the summers were very warm.

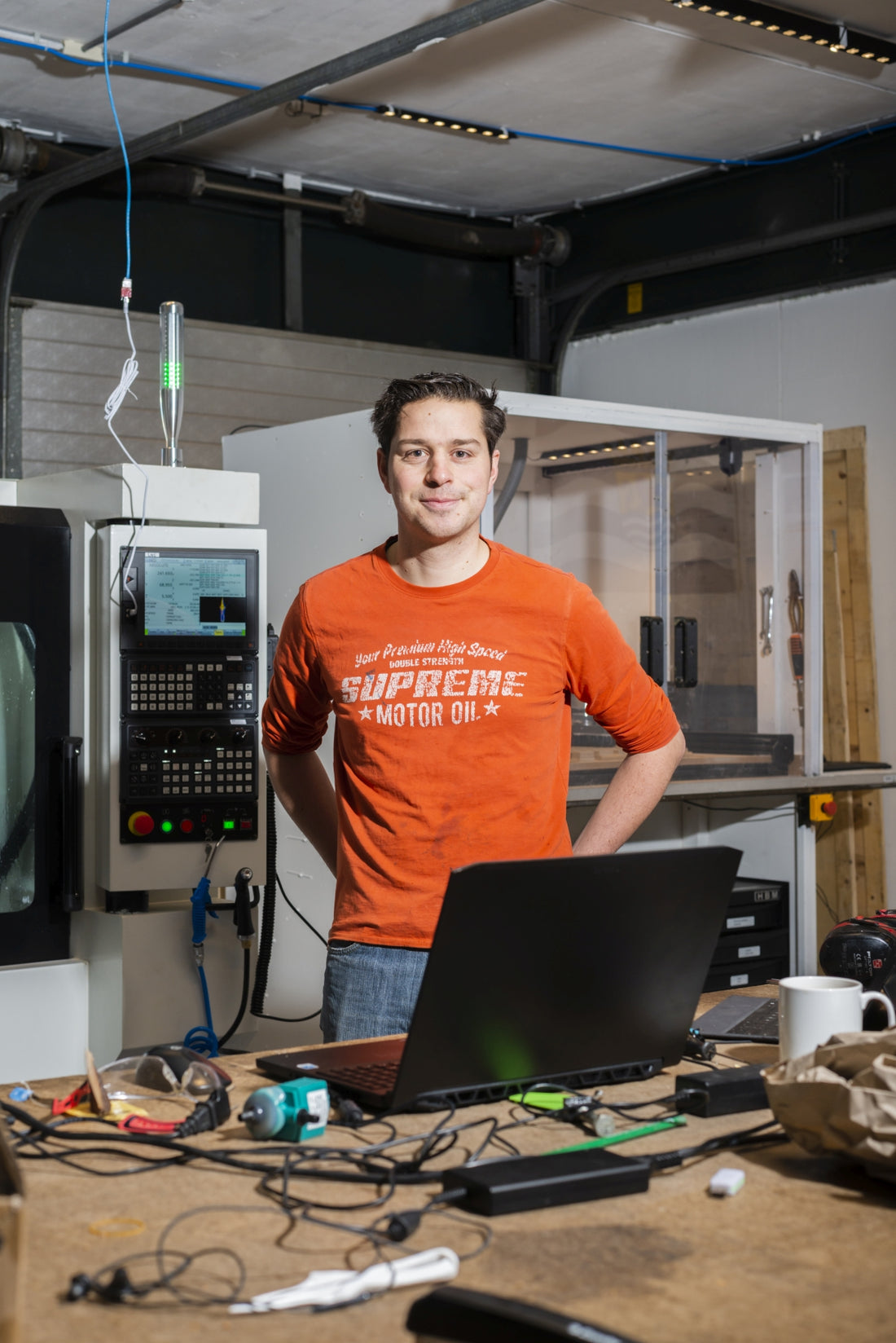

So for my new workshop I hired a space with a fixed contract term. We painted the walls and the floor, added running water and LED lighting and arranged the machines in the perfect way to efficiently make oyster shuckers. It was also in this workshop that I received the Syil X7-20 epoxy granite CNC milling machine. This machine should allow me to develop new products and grow the number of knives that I can make.

Why? Because I want to become a fulltime oyster knife maker. Oysters are in my DNA, and although I’m not growing them like my nephew and uncle, I do want to dedicate myself to this wonderful product of the sea. Emergo Designs has been making oyster opening tools for 7+ years, and I can’t wait to get my unique and elegant knives in the hands of more people.