I bought my CNC router in 2019 and it was a great first step into the world of machining. But my company grew and so did the new machines that came in. A VMC and CNC lathe, then the litte Ooznest Workbee router looks petty. The accuracy was always great, but it's very slow. However, it only runs a couple of days a month.

So why buy a faster router when you can run it more often? Instead of buying the Ratrig Stronghold Pro, I improved a lot of steps in my process. I made a complete excel sheet with every step required until the first part was running. This was around 45 minutes and 8 minutes to reload a part. With all the improvements that were made, the Workbee only takes five minutes to get ready. The warm-up cycle is programmed in the code of the first part. Now I don't need another CNC router!

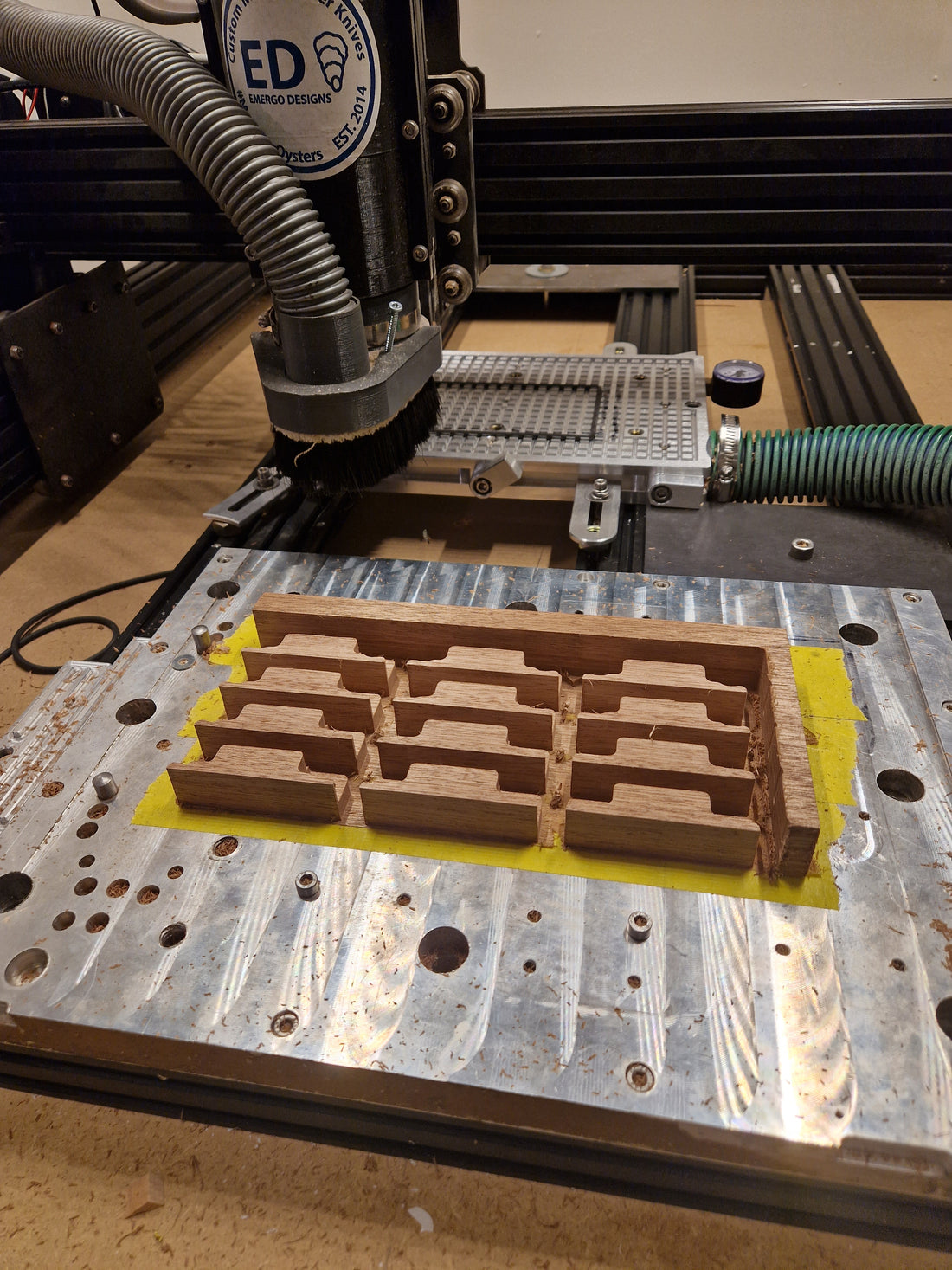

And most important: I have more flexibility to produce and ship oyster opening tools. I you want a personalized case, a different material or you need it before Friday because you have a wedding(this happens remarkably often!!), having a machine that's easy to run helps. Therefore improving the process will help me get my product in the hands of more oyster lovers.

And as you can see in this Instagram post, the improvement process keeps continuing. I hope you found this an interesting insight in the technical side of oyster knife making. Kind regards, Alexander