Meet the Hugo full titanium Oyster Knives

"Sculped" out of a solid block of titanium and 100% circular.

Packaging Matters

Our cases are made 100% in house on our CNC router and they make this oyster knife ideal as a unique gift. To yourself or to someone else!

We have the possibility to do logos and engravings on the cover to make this oyster opening tool even more special.

My Story

-

Read More About Emergo Designs

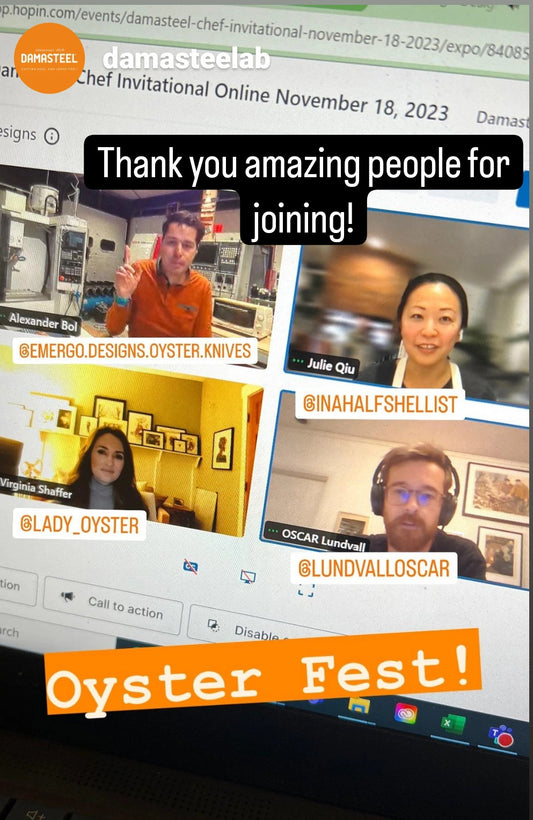

My name is Alexander Bol. Our family has been growing and fishing oysters for 100+ years in the Netherlands. We fish and grow shellfish in the the Eastern Scheldt region. As a child I happily spent my summers working on our family’s oyster fishing ship. Moreover it’s special to be working out on the water and I look back with great memories.

Growing up, I took an interest in designing and making products. Therefore I became an engineer and combined my passion for knife making with my family heritage. In 2014 I developed my first oyster knife.

On a fine Sunday afternoon, my dad broke his cheap oyster shucker. Most importantly he was lucky that he didn’t hurt himself. However upon investigation I heard more stories about people hurting themselves while shucking oysters. This led me to create a durable and unique custom made oyster knife.

In 2014 I was already into knifemaking, but I chose to specialize in products for oysters. Customers use Emergo Designs shuckers worldwide, from Japan to the United states. In conclusion I can say that I’m very happy with the inspiration of that one broken knife.

-

Alexander Bol

Photo by: Mechteld Jansen

Meet the Enduris, traditional and modern Oyster Knives.

The successor to the knife that started Emergo Designs in 2014.

Meet the Jacomina, a very special edition Damasteel Oyster Knife

A intricate blend between unique materials and Dutch Design.

Made For Oyster

The Jacomina Oyster Knife

Follow me on Instagram

For behind the scenes pictures and updates!

View Our Collections

-

The Hugo Oyster Knives

The Hugo Full Titanium Oyster Knife is a premium oyster knife. This...